Start with Casella – Retire with Casella

Why Casella?

-

Facilities Maintenance Technician

The Facilities Technician utilizes knowledge of mechanical, electrical, and hydraulic equipment Facilities Technician will install, maintain, troubleshoot, and repair machinery or equipment, diagnose issues with machinery components, and determine when adjustments or repairs are needed. The incumbent will have an increasing level of responsibility with an increase in experience and expertise.

B Technician: Demonstrates the ability and shows a complete understanding of Level C skills and equipment, while showing an increasing amount of knowledge of Level B Skills. Level C mechanical skills include grease bearings, knowledge of types of belts, lubrication (gear oils), ladders, and use of all lifts and filter carts. Level C electrical skills include knowledge of wire sizes, splice connectors, knowledge of voltages, ability to read labels on sub-panels to find the main supply, ability to reset breakers, and what to do if they continue to trip.

A Technician: Demonstrates the ability and shows a complete understanding of Level B skills and equipment, while beginning to show an increasing amount of knowledge of Level A skills. Level B mechanical skills and equipment include use of calipers, an understanding of reading name plates, changing bearings, gearboxes, shafts, pulleys, and conveyor belts, welding with torches, use of a hydraulic wrench, changing motors, voltmeter, hydraulic solenoids, changing coils, diagnose motors or gearboxes, making hydraulic hoses, and LOTO. Level B electrical skills and equipment include colt and multimeter, wire all motors and voltage, trouble-shooting motors, test fuses, change starters, overloads, input/output cards, program UFDs, run and bend conduit, wire motor as “Y” Delta, read name plates and change breakers in panels.

Master Technician: Demonstrates the ability to complete and understand all Level C, B, and A skills and equipment. Level A mechanical skills include vertical weld and overhead weld with stick, diagnose dialed motor, gearbox and pumps, rebuilds gearbox, solenoids, motors, pumps (hydraulic/water), reads hydraulic schematics, welds 1/2” steal or larger. Level A electrical skills and equipment include: Electrical schematics, low voltage, control wiring, 480/240/120 volts circuits, isolation tests on motors, diagnose circuits, conduit size, wire size, and wire count, wire a new panel by the schematic, and load calculation and balance panels. A Master Technician should also demonstrate the ability to successfully lead and train a small team.

-

Diesel Technician

Lead TechnicianMaster TechnicianTechnician ATechnician BApprentice TechnicianRequired to advance:

Lead TechnicianMaster TechnicianTechnician ATechnician BApprentice TechnicianRequired to advance:

Demonstrated ability to lead and manage people and tasks, thorough knowledge of electrical, diagnostic, and multiplex systems, web-based training, and proficient knowledge

of all lines and makes of equipmentRequired to advance:

Proficient knowledge of electrical systems, proficient knowledge of diesel engine, transmission, and suspension systems, web-based training, and proficient knowledge

of 4 lines and makes of equipmentRequired to advance:

Mid-level knowledge of technical and measuring tools, ABS/EPS stability systems training, catalyst/non-catalyst/exhaust treatment (EATS) training, and proficient knowledge of Mack and 2 other makes of equipmentRequired to advance:

Basic knowledge of electrical systems, brake, transmission, engine, suspension training, and proficient knowledge of Mack’s equipmentRequired to advance:

State inspection certification, previous maintenance training, and lubricant/coolant/anti-freeze training

Lead TechnicianMaster TechnicianTechnician ATechnician BApprentice TechnicianThoroughly identifies defects requiring corrections which affect the operation and safety of all equipment. Inspects, troubleshoots, and repairs all vehicle and equipment systems. Rebuilds and replaces engines and engine components, transmissions, drive line and rear-ends, mechanical systems, electrical systems, and hydraulic components. Develops mechanic training plans and coaches employees to achieve successful outcomes.Inspects, troubleshoots, and repairs all vehicle and equipment systems. Rebuilds and replaces engines and engine components, transmissions, drive line and rear-ends, mechanical systems, electrical systems, and hydraulic components.Inspects, troubleshoots, and repairs vehicle brakes, suspension, steering, tires, springs, rims, hubs, PTO, hydraulics, engine cooling, starting, ignition, charging, lighting systems, fuel and air intake systems, heating, ventilation and cooling systems to ensure vehicles are in safe and dependable operating condition.Identifies and corrects vehicle operating issues including examining, test driving and troubleshooting electrical and mechanical problems using standard testing procedures and computer diagnostic equipment.Maintains vehicles in safe, dependable operating condition by performing regular service and preventative maintenance according to safety and compliance guidelines and requirements. Includes conducting safety inspections, maintaining vehicle appearance, performing regular service, and completes

Lead TechnicianMaster TechnicianTechnician ATechnician BApprentice TechnicianThoroughly identifies defects requiring corrections which affect the operation and safety of all equipment. Inspects, troubleshoots, and repairs all vehicle and equipment systems. Rebuilds and replaces engines and engine components, transmissions, drive line and rear-ends, mechanical systems, electrical systems, and hydraulic components. Develops mechanic training plans and coaches employees to achieve successful outcomes.Inspects, troubleshoots, and repairs all vehicle and equipment systems. Rebuilds and replaces engines and engine components, transmissions, drive line and rear-ends, mechanical systems, electrical systems, and hydraulic components.Inspects, troubleshoots, and repairs vehicle brakes, suspension, steering, tires, springs, rims, hubs, PTO, hydraulics, engine cooling, starting, ignition, charging, lighting systems, fuel and air intake systems, heating, ventilation and cooling systems to ensure vehicles are in safe and dependable operating condition.Identifies and corrects vehicle operating issues including examining, test driving and troubleshooting electrical and mechanical problems using standard testing procedures and computer diagnostic equipment.Maintains vehicles in safe, dependable operating condition by performing regular service and preventative maintenance according to safety and compliance guidelines and requirements. Includes conducting safety inspections, maintaining vehicle appearance, performing regular service, and completes

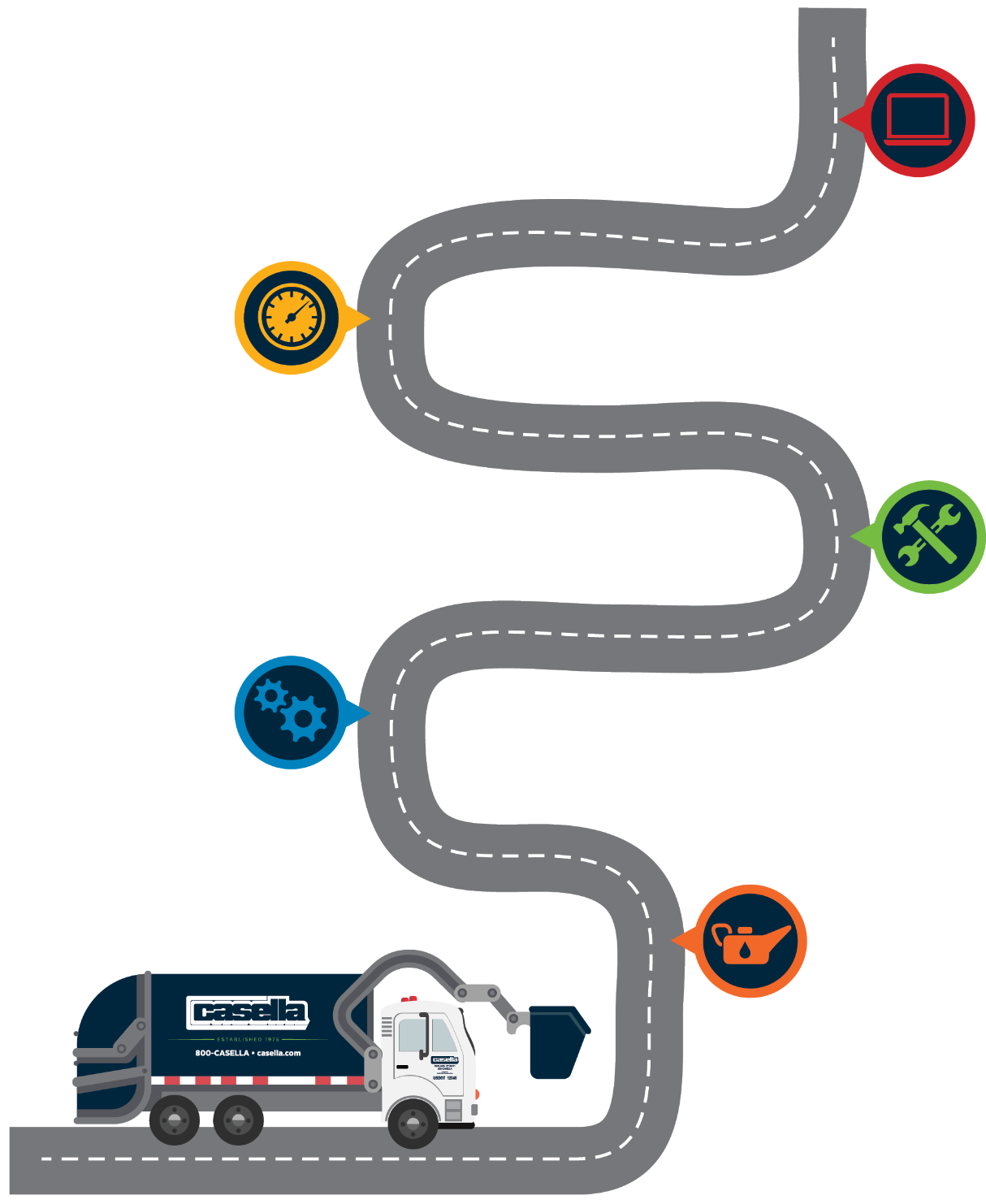

service records.TECHNICIAN CAREERPATH PROGRESSIONTECHNICIAN CAREERPATH LEVELS -

Heavy Equipment Technician

The Heavy Equipment Technician performs repairs and preventative maintenance and corrections on heavy equipment, compact heavy equipment, light service equipment, and light trucks. Typical repairs include, but are not limited to, preventative maintenance inspections, hydraulic, fuel, exhaust, brakes, suspension, electrical, HVAC, and emission systems.

Apprentice: Technician will assist other technicians with preventative and corrective maintenance on fleet vehicles, and equipment including gas and diesel engines, hydraulic systems, air brakes, forklifts, and trailers.

Technician B: Technician will complete parts changing tasks such as adjusting tracks properly for wear, changing out the roller on the undercarriage on machinery, determining if track sprockets are good or need to be replaced, servicing cab pressurizers and determining the effectiveness, evaluating oil sample reports, changing out the alternator and starter, assembling hydraulic hose, and ordering parts.

Technician A: Technician will complete basic diagnostics. Jobs will include tasks such as replacing components, welding, cutting and fabrication, working on engine transmissions, final drives, completing basic diagnostics for lights, starter etc. Replacing undercarriage, performing fuel system repairs, and diagnose and determine source of oil contamination and complete repairs.

Master Technician: Technician will complete advanced diagnostics. Jobs will include tasks such as diagnosing and repairing engine faults, determining the cause of wear on tracks, working to improve track life, trouble shooting and repairing ECM, hydraulic issues, AC systems, emission systems and diagnosing and repairing drive lift.

Testimonials